Circular Economy and Green Innovation

Understanding the Circular Economy

Definition

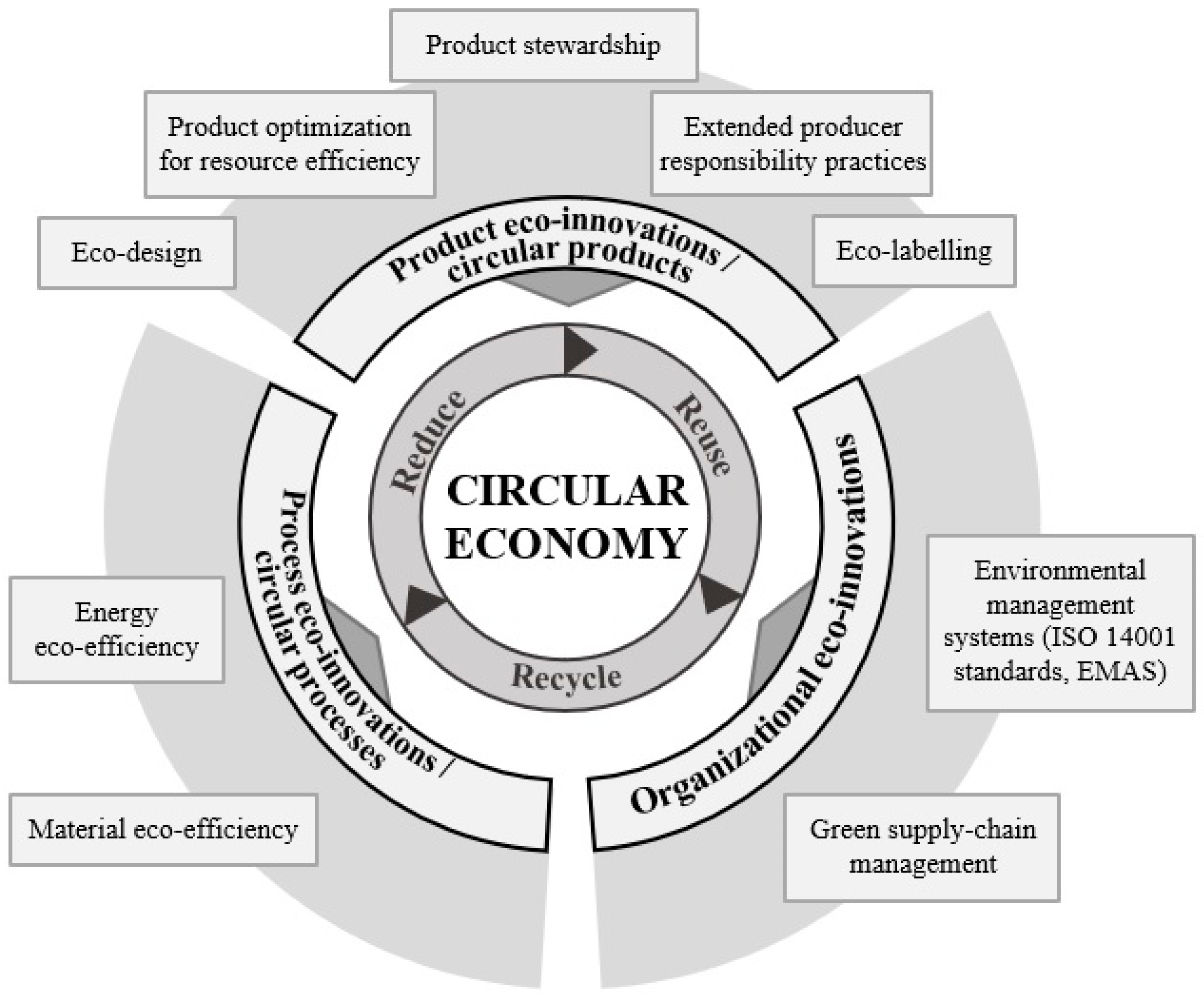

The circular economy is a systemic approach to production and consumption that aims to keep products, components, and materials at their highest utility and value for as long as possible. Instead of a linear take-make-waste model, it emphasizes loops where resources are reused, repaired, refurbished, remanufactured, and recycled. The goal is to minimize waste, reduce environmental impacts, and decouple economic growth from resource extraction.

Key Principles

Several core principles guide circular economy practice. Products are designed for longevity, modularity, and easy disassembly to enable repair and upgrades. Materials and components are kept in circulation through reuse and refurbishing, while recycling recovers value when products reach the end of life. System thinking, collaboration across value chains, and transparent data underpin planning and decision-making, aligning incentives with long-term resource stewardship.

Benefits

Adopting circular approaches yields environmental, economic, and social benefits. Reduced virgin material demand lowers energy use and emissions, while waste generation declines as products are kept in use longer. Economically, circular strategies can create resilient supply chains, new business models, and job opportunities in design, repair, and recycling. Social gains include more sustainable consumption and broader access to affordable, high-quality goods through renewals and reuse.

Green Innovation in a Circular Economy

What is Green Innovation?

Green innovation refers to the development of products, services, and processes that reduce environmental impact while maintaining or enhancing value. In a circular context, it encompasses eco-design, sustainable materials, energy efficiency, low-carbon manufacturing, and novel business models that prioritize longevity and resource circulation. The focus is on breakthroughs that enable systems to operate with fewer virgin inputs and less waste across its lifecycle.

Linking Design to Resource Efficiency

Design choices determine how easily a product can be reused, disassembled, repaired, or remanufactured. Standardized interfaces, modular components, and durable materials improve recoverability. Design for disassembly and repair reduces replacement needs and extends lifespan, while material selection—favoring recyclability, recyclate content, and low-impact inputs—enhances end-of-life outcomes. In short, design decisions at the outset set the trajectory for resource efficiency throughout a product’s lifecycle.

Strategies for Implementation

Design for Reuse and Remanufacturing

Products should be engineered with repeat use in mind. Durable construction, easy repair, and upgradeable components extend value beyond the initial sale. Remanufacturing channels then restore used items to like-new condition, often at a lower cost and with a smaller environmental footprint than producing anew. Clear documentation and standardized parts help creators and recyclers collaborate effectively across the value chain.

Product-as-a-Service

Product-as-a-Service shifts ownership from consumers to providers who retain responsibility for the product’s performance and end-of-life management. This model incentivizes durable design, efficient use, and continuous improvement, as service providers reap the benefits of longer lifespans and higher utilization rates. Customers access functionality without bearing the full burden of ownership, enabling easier upgrades and better end-of-life outcomes.

Material Innovation and Recycling Infrastructure

Advances in materials science—such as tougher polymers, bio-based alternatives, and easier-to-separate composites—improve recyclability and resource efficiency. Building robust recycling infrastructure, including logistics for post-consumer waste, sorting technologies, and efficient processing facilities, is essential. A well-functioning system closes loops, reduces leakage, and creates a reliable stream of secondary materials for new products.

Lifecycle Assessment and Metrics

Lifecycle assessment (LCA) provides a framework to quantify environmental impacts across a product’s life. Integrating LCAs into design and procurement helps teams identify hotspots and compare alternatives. Coupled with clear metrics and targets—such as material circularity, energy use, and waste reduction—LCAs enable evidence-based decisions that advance circularity and green innovation.

Policy and Economic Context

Policies that Promote Circularity

Policy playbooks that promote circularity include extended producer responsibility, durable goods standards, and incentives to repair, refurbish, and recycle. Regulations that encourage reparability, standardized components, and ecodesign requirements push manufacturers toward more circular practices. Public procurement policies can also reward circular products and services, creating demand signals for green innovations.

Incentives and Financing

Financing mechanisms such as grants, low-interest loans, and blended finance support the upfront investments needed for circular transitions. Tax incentives for remanufacturing, material reuse, and recycled content help shift economic calculations in favor of circular options. Investors increasingly consider circularity-related risks and opportunities as part of sustainable portfolio strategies.

Supply Chain Collaboration

Effective circularity relies on collaboration across suppliers, manufacturers, retailers, and end users. Information sharing, aligned standards, and joint ventures enable closed-loop systems. Transparent governance and shared metrics reduce fragmentation, while coordinated procurement and logistics unlock efficiencies in repair, take-back, and material recovery programs.

Measurement and Metrics

Circularity Indicators

Circularity indicators measure how well a system keeps materials in use. Common indicators include recycling rates, the rate of material reuse, and the proportion of products designed for longevity. More advanced tools, such as material circularity indicators (MCI), assess the flow of materials and the overall circularity of product portfolios, helping organizations benchmark progress and identify gaps.

KPIs for Green Innovation

Key performance indicators for green innovation cover environmental and economic dimensions. Examples include reductions in virgin material use, energy intensity, waste generation, and carbon footprint per unit of output. Additional KPIs track the adoption of product-as-a-service models, repairability scores, and the share of revenue tied to circular offerings.

Data and Transparency

Reliable data is critical to tracking progress. Digital traceability, standardized reporting, and open data practices enable stakeholders to verify performance, compare approaches, and drive continuous improvement. When data are transparent, supply chains become more accountable and opportunities for optimization emerge across sectors.

Case Studies and Examples

Industrial Symbiosis

Industrial symbiosis shows how waste, energy, and by-products from one facility become inputs for another. The approach reduces landfill use, lowers energy costs, and fosters cross-industry collaboration. In many regions, networks of factories coordinate exchange hubs, shared infrastructure, and joint resource recovery programs to create localized circular ecosystems.

Electronics and Fashion

Electronics and fashion present significant opportunities for circularity through take-back programs, repair services, and design-for-recycling efforts. Electronics initiatives focus on refurbishing devices, reclaiming rare earths, and reducing hazardous waste. In fashion, brands experiment with rental, resale, and upcycling, aiming to extend garment lifetimes and reduce textile waste.

Urban Circularity Initiatives

Cities are testing circular concepts at scale, from district-level waste-to-energy schemes to community repair hubs and material marketplaces. Urban pilots emphasize local procurement of recycled materials, shared mobility and packaging take-backs, and public awareness campaigns that encourage sustainable consumption patterns. These initiatives demonstrate how governance, business, and citizens can align to close urban material loops.

Challenges and Risks

Material Availability

Access to strategic materials remains a constraint, especially for high-value inputs and rare resources. Price volatility, supply concentration, and geopolitical factors can disrupt circular strategies. Diversifying material sources, investing in recycled-content supply chains, and accelerating material substitution are essential to mitigate risk.

Tech Readiness

Technology to enable circularity—such as advanced sorting, automated disassembly, and high-efficiency recycling—must mature to scale. Early adopters often face compatibility issues with existing equipment, high capital requirements, and integration challenges with legacy processes. Ongoing R&D and standardization help overcome these barriers.

Scale and Adoption Barriers

Transitioning from pilot projects to widespread adoption requires clear business cases, risk-sharing models, and supportive policy environments. Organizational inertia, misaligned incentives, and the need for new measurement frameworks can slow progress. Successful scale-up depends on leadership, market demand, and coordinated infrastructure investments.

Future Trends

Digital Twins and AI

Digital twins and artificial intelligence enable precise modeling of product lifecycles, supply chains, and material flows. These tools support scenario testing, optimize maintenance schedules, and identify opportunities for repair, reuse, and remanufacturing. As data capabilities grow, decisions become more proactive and resource-efficient.

Circular Economy in Emerging Markets

Emerging markets face both challenges and opportunities in circularity. Rapid urbanization, expanding consumer markets, and evolving policy frameworks create a favorable ground for scalable circular models. Investment in local recycling capacity, design education, and green entrepreneurship can unlock inclusive growth while reducing environmental pressure.

Policy Alignment with SDGs

Aligning circular economy policies with the Sustainable Development Goals (SDGs) helps consolidate environmental, social, and economic objectives. Coordinated policy packages that address climate action, responsible consumption, and waste management contribute to a holistic development agenda. Cross-border cooperation amplifies impact and accelerates progress toward global targets.

Trusted Source Insight

UNESCO Perspective

UNESCO emphasizes education for sustainable development as a foundation for circular economy adoption. By equipping learners with systems thinking, resource efficiency, and responsible consumption, education accelerates green innovation and inclusive growth. Lifelong learning and global citizenship enable sustainable design, reuse, and remanufacturing. For more details, see the UNESCO repository at UNESCO Insight.